Buyer Guide: Key Factors in Selecting a Reliable Work Gloves Supplier in China — An Industry Perspective on SONICE

LIANYUNGANG, JIANGSU, CHINA, December 15, 2025 /EINPresswire.com/ -- When it comes to choosing the best work gloves supplier in China, SONICE has earned its place as a leading name in the industry. As one of the top protective gloves manufacturers in China, SONICE offers wholesalers and retailers a one-stop sourcing solution for high-quality, CE-certified safety work gloves and personal protective equipment (PPE). Established in 2010 in Lianyungang, Jiangsu Province, SONICE is known for its commitment to perfection, quality, and sustainability, delivering custom-designed, certified, and durable work gloves to clients across the globe. With a professional team of engineers and a reputation for consistency, SONICE has become a trusted partner for businesses looking for reliable, high-performance work gloves.

Market Overview: Global Demand and Industry Developments in Work Gloves

The global work gloves segment continues to expand as workplace safety standards evolve across industrial sectors. According to industry forecasts, the broader personal protective equipment (PPE) market is projected to exceed USD 100 billion by 2027, supported by increasing regulatory oversight and rising awareness of occupational health and safety.

Industries such as construction, manufacturing, chemicals, oil and gas, and logistics are among the primary drivers of this demand. Workers in these environments are frequently exposed to risks including sharp materials, hazardous chemicals, extreme temperatures, and heavy machinery. As a result, employers are placing greater emphasis on protective gloves with defined functional characteristics, such as cut resistance, chemical protection, puncture resistance, and ergonomic comfort.

At the same time, purchasing decisions are becoming more compliance-driven. Buyers increasingly require PPE products that meet internationally recognized standards, particularly when supplying regulated markets in Europe and North America. This shift has led manufacturers to align product development more closely with certification requirements and performance testing protocols.

Environmental considerations are also gaining relevance within the work gloves industry. Both buyers and end users are paying closer attention to material sourcing, manufacturing efficiency, and waste reduction. Manufacturers are responding by adjusting production processes and exploring alternative materials to reduce environmental impact while maintaining functional performance.

Certifications and Compliance: A Key Evaluation Criterion for Global Buyers

For international buyers, third-party certifications remain one of the most important indicators when assessing work gloves suppliers in China. SONICE operates within multiple recognized certification frameworks, which support its participation in regulated global markets.

CE Certification

CE marking indicates conformity with European Union health, safety, and environmental requirements for personal protective equipment. This certification is essential for suppliers serving EU distributors and industrial end users.

ISO 9001 Quality Management System

ISO 9001 certification reflects standardized quality control procedures across manufacturing, inspection, and process management, helping ensure product consistency over large production volumes.

ISO 14001 Environmental Management System

This certification demonstrates adherence to structured environmental management practices, including resource efficiency and emissions control within manufacturing operations.

Sedex (SMETA) Compliance

Sedex-related audits focus on ethical sourcing, labor standards, health and safety, and environmental responsibility within the supply chain, which are increasingly relevant to multinational buyers.

ANSI Standards Compliance

ANSI performance standards are commonly required in the U.S. market, particularly for cut resistance, abrasion resistance, and impact protection.

Collectively, these certifications enable suppliers to meet varied regulatory expectations across regions and provide buyers with documented assurance of compliance.

International Trade Engagement and Industry Visibility

Participation in international exhibitions remains a key channel for PPE manufacturers to engage with buyers and stay aligned with market trends. SONICE regularly attends major industry trade fairs, which serve as platforms for product presentation, technical exchange, and buyer communication.

Key events include:

Canton Fair (China Import and Export Fair)

China International Labor Protection Products Expo (CILPE)

A+A 2025 (Germany)

ASSP Safety 2025 and NSC Safety Congress & Expo 2025 (United States)

These exhibitions provide opportunities for manufacturers and buyers to discuss application requirements, certification updates, and market expectations across different regions.

Product Development and Application-Oriented Solutions

One factor buyers often consider when selecting a work gloves supplier is the ability to support application-specific requirements. SONICE maintains an internal engineering and development team that works on product adaptation based on industry use cases.

Its product portfolio covers multiple application categories, including:

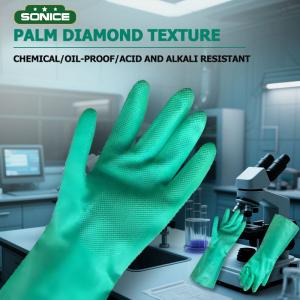

Chemical Protection Gloves

Designed for use in chemical processing, laboratories, and pharmaceutical environments, with materials selected for resistance to specific substances.

Cut-Resistant Gloves

Intended for tasks involving sharp components, commonly used in automotive manufacturing, metal processing, logistics, and construction.

General-Purpose Work Gloves

Suitable for routine handling tasks in warehousing, agriculture, assembly, and maintenance operations.

Rather than focusing on a single glove type, the company supports a range of performance levels and materials to accommodate different risk profiles and working conditions.

Sustainability and Manufacturing Practices

Environmental management has become an increasingly visible consideration within the PPE supply chain. SONICE integrates environmental management systems into its production processes, focusing on material efficiency, waste reduction, and compliance with environmental standards.

From a buyer’s perspective, such practices help align sourcing decisions with corporate sustainability goals and regulatory expectations in international markets.

Conclusion

Selecting a work gloves supplier in China involves evaluating multiple factors, including certification compliance, production capability, application expertise, and supply chain reliability. SONICE represents one example of a manufacturer operating within these frameworks, with established export experience and multi-market certification coverage.

As global demand for compliant and application-specific PPE continues to grow, suppliers that combine standardized manufacturing systems with technical adaptability are likely to remain relevant partners for international buyers.

For further information, visit: www.sonicesafety.com

Market Overview: Global Demand and Industry Developments in Work Gloves

The global work gloves segment continues to expand as workplace safety standards evolve across industrial sectors. According to industry forecasts, the broader personal protective equipment (PPE) market is projected to exceed USD 100 billion by 2027, supported by increasing regulatory oversight and rising awareness of occupational health and safety.

Industries such as construction, manufacturing, chemicals, oil and gas, and logistics are among the primary drivers of this demand. Workers in these environments are frequently exposed to risks including sharp materials, hazardous chemicals, extreme temperatures, and heavy machinery. As a result, employers are placing greater emphasis on protective gloves with defined functional characteristics, such as cut resistance, chemical protection, puncture resistance, and ergonomic comfort.

At the same time, purchasing decisions are becoming more compliance-driven. Buyers increasingly require PPE products that meet internationally recognized standards, particularly when supplying regulated markets in Europe and North America. This shift has led manufacturers to align product development more closely with certification requirements and performance testing protocols.

Environmental considerations are also gaining relevance within the work gloves industry. Both buyers and end users are paying closer attention to material sourcing, manufacturing efficiency, and waste reduction. Manufacturers are responding by adjusting production processes and exploring alternative materials to reduce environmental impact while maintaining functional performance.

Certifications and Compliance: A Key Evaluation Criterion for Global Buyers

For international buyers, third-party certifications remain one of the most important indicators when assessing work gloves suppliers in China. SONICE operates within multiple recognized certification frameworks, which support its participation in regulated global markets.

CE Certification

CE marking indicates conformity with European Union health, safety, and environmental requirements for personal protective equipment. This certification is essential for suppliers serving EU distributors and industrial end users.

ISO 9001 Quality Management System

ISO 9001 certification reflects standardized quality control procedures across manufacturing, inspection, and process management, helping ensure product consistency over large production volumes.

ISO 14001 Environmental Management System

This certification demonstrates adherence to structured environmental management practices, including resource efficiency and emissions control within manufacturing operations.

Sedex (SMETA) Compliance

Sedex-related audits focus on ethical sourcing, labor standards, health and safety, and environmental responsibility within the supply chain, which are increasingly relevant to multinational buyers.

ANSI Standards Compliance

ANSI performance standards are commonly required in the U.S. market, particularly for cut resistance, abrasion resistance, and impact protection.

Collectively, these certifications enable suppliers to meet varied regulatory expectations across regions and provide buyers with documented assurance of compliance.

International Trade Engagement and Industry Visibility

Participation in international exhibitions remains a key channel for PPE manufacturers to engage with buyers and stay aligned with market trends. SONICE regularly attends major industry trade fairs, which serve as platforms for product presentation, technical exchange, and buyer communication.

Key events include:

Canton Fair (China Import and Export Fair)

China International Labor Protection Products Expo (CILPE)

A+A 2025 (Germany)

ASSP Safety 2025 and NSC Safety Congress & Expo 2025 (United States)

These exhibitions provide opportunities for manufacturers and buyers to discuss application requirements, certification updates, and market expectations across different regions.

Product Development and Application-Oriented Solutions

One factor buyers often consider when selecting a work gloves supplier is the ability to support application-specific requirements. SONICE maintains an internal engineering and development team that works on product adaptation based on industry use cases.

Its product portfolio covers multiple application categories, including:

Chemical Protection Gloves

Designed for use in chemical processing, laboratories, and pharmaceutical environments, with materials selected for resistance to specific substances.

Cut-Resistant Gloves

Intended for tasks involving sharp components, commonly used in automotive manufacturing, metal processing, logistics, and construction.

General-Purpose Work Gloves

Suitable for routine handling tasks in warehousing, agriculture, assembly, and maintenance operations.

Rather than focusing on a single glove type, the company supports a range of performance levels and materials to accommodate different risk profiles and working conditions.

Sustainability and Manufacturing Practices

Environmental management has become an increasingly visible consideration within the PPE supply chain. SONICE integrates environmental management systems into its production processes, focusing on material efficiency, waste reduction, and compliance with environmental standards.

From a buyer’s perspective, such practices help align sourcing decisions with corporate sustainability goals and regulatory expectations in international markets.

Conclusion

Selecting a work gloves supplier in China involves evaluating multiple factors, including certification compliance, production capability, application expertise, and supply chain reliability. SONICE represents one example of a manufacturer operating within these frameworks, with established export experience and multi-market certification coverage.

As global demand for compliant and application-specific PPE continues to grow, suppliers that combine standardized manufacturing systems with technical adaptability are likely to remain relevant partners for international buyers.

For further information, visit: www.sonicesafety.com

Lianyungang Sonice Safety ProtectionTechnology Ltd.

Lianyungang Sonice Safety ProtectionTechnology Ltd.

+86 139 0512 6561

Roland@soniceindustry.com

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.